Let’s assume you have $90,000 worth of inventory at the start of the year. Your COGS figure will also depend on whether you’re usingįirst in, first out (FIFO), last in, first out (LIFO) or another type of inventory costing method.Ĭost of inventory at the beginning of the year + additional inventory costs (purchases during the year) – cost of inventory at the end of the year = Cost of goods sold COGS excludes salaries and general administrative costs. In other words, the total cost of producing the products materials, labor, and other related expenses.

INVENTORIES TURNOVER RATIO FORMULA HOW TO

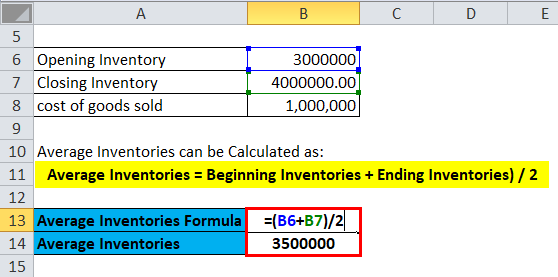

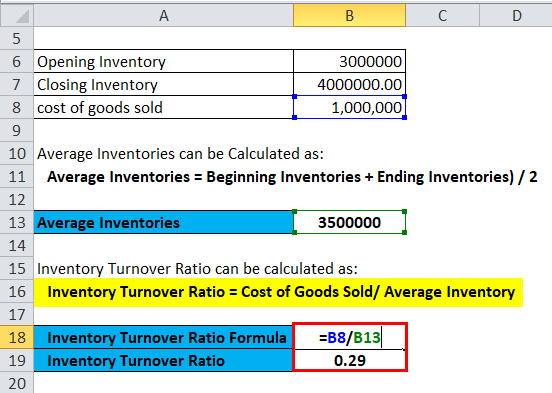

How to calculate the cost of goods soldĬOGS calculates all the direct costs involved in selling a product. You can apply a few simple formulas to your existing data, especially once you understand the best practices for turnover analysis.īefore we jump into the calculations, let’s review the two monetary terms you will need for this calculation - the cost of goods sold (COGS) and your average inventory. The good news is that you don’t need an elaborate system or a specialized inventory turnover calculator to determine inventory turns. Tracking inventory turnover also helps you anticipate market changes and proactively adjust inventory levels, giving you more time to secure orders, renegotiate agreements or find alternatives. You can recognize and respond to underperformance faster, which minimizes potential losses or supply issues. Thorough knowledge of inventory turnover informs how you optimize your operations so that the right products are in stock at the ideal levels to meet demand. This better positioning also helps with a variety of other business decisions. When you reduce holding costs and understand purchasing trends, you’re well-equipped to meet consumer demand and establish a competitive advantage. Overhead expenses such as storage fees or expedited shipping costs can be limited or even eliminated with a better understanding of your stock turnover and improved inventory management. Improving your inventory turnover ratio can directly contribute to greater profitability.

Understanding the ever-changing needs of your customers requires careful planning and execution, and inventory turnover is a central part of meeting those needs. It seems simple, but anyone who’s tried to make sales forecasts knows it’s not always easy. The goal for most retailers is to sell as many products to as many customers as reasonably possible. Why does inventory turnover matter to your ecommerce business? That prioritization could affect your spending on active and planned marketing campaigns, while your customer service team receives fewer complaints when high-turnover products are readily available. Slow-moving inventory, meanwhile, can be discounted to make room for more profitable items. This metric helps you make decisions about inventory levels and drive other business decisions related to warehouses, fulfillment, marketing and customer service.įor example, products with high inventory turnover ratios should be optimally positioned in warehouses for quick fulfillment. In essence, inventory turnover measures how fast you sell inventory during a given period. While you can measure inventory movement over a month or quarter, many inventory turnover calculations rely on yearly inventory data. They all refer to inventory ratios reflecting the number of times your products are sold and replaced in a given period. Inventory turnover is known by several names, including inventory turnover ratio, stock turnover, inventory turn or stock turn. Learn more about inventory turnover, how it applies to your business, common calculations and how you can improve this metric. And when you know the key calculations, you can benchmark your industry turnover against your industry’s specific circumstances.

Reviewing inventory turnover is an essential step in effective inventory management, which helps you fulfill orders, keep inventory in balance and plan for business milestones such as adding locations or product lines. Do you know how to calculate inventory turnover? This critical business metric informs your day-to-day inventory management decisions and strategies to help you continue to scale.

0 kommentar(er)

0 kommentar(er)